The Black Forest-based company August Weckermann KG has installed its own renewable energy supply, and the hydrogen tanks are fitted with HEROSE safety valves.

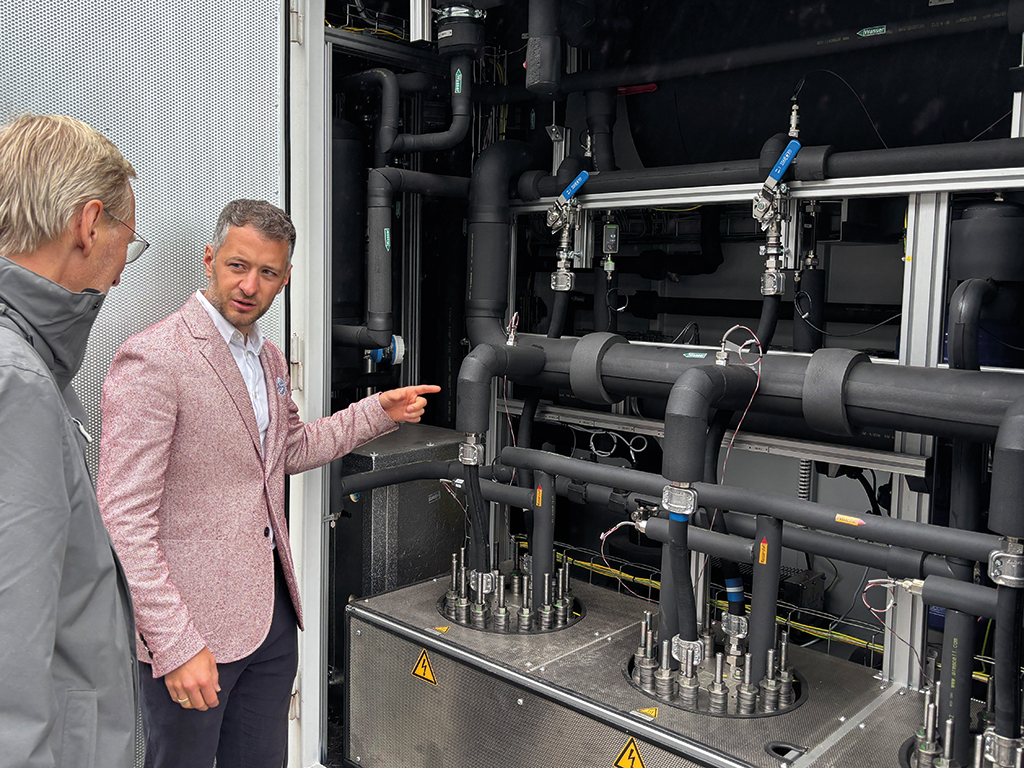

Inside August Weckermann KG, each diamond-polished part shines brighter than the next while, outside, the gleaming black photovoltaic modules convert sunlight into energy. The family company is a global market leader in diamond machining and has implemented a comprehensive energy concept to become as self-sufficient and climate-neutral as possible in generating the electricity required for production.

Black Forest originality

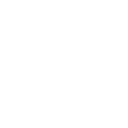

The spark for the idea came from the size of the site on which the new production facility and offices were to be built. The question was what to do with the space not being built on. It was proposed to install photovoltaics to generate electricity. But it didn’t stop at that: the Black Forest company went all out with their energy concept – a high-powered photovoltaic system, a redox-flow battery for buffer storage, an electrolyser fed with purified rainwater, four hydrogen tanks, one fire water tank for buffer storage and a heat pump. Let’s look at how it all came about.

Brilliant solutions – not just when it comes to energy

The Weckermann firm started out making parts for the clock and watch industry 140 years ago – which at that time included components for Black Forest cuckoo clocks. Today the company specialises in diamond machining, a high-precision grinding method using diamond tools. A diamond-polished part features a mirror finish, ultra-smooth surface and maximum dimensional accuracy. Its more than 120 customers include renowned sanitary ware producers and manufacturers of fine writing instruments; not only that, but high-quality packaging and product blends are made on its more than 200 different machines and CNC machining centres.

Independence and planning certainty

Events of recent years have brought it home to small and medium-sized enterprises that independence and price stability are important factors in energy supply. High energy requirements and the expectation that prices will continue to rise create financial pressures that could jeopardise competitiveness in the long term. In addition, the two or three power cuts that have happened every year have caused damage to machinery. There is therefore a logical rationale for investment in a comprehensive energy solution, plus it is a pet project of company heads, Karl Duttlinger and his son David: “We are pressing ahead with plans and hope to inspire others.“

Pioneers in the area of energy

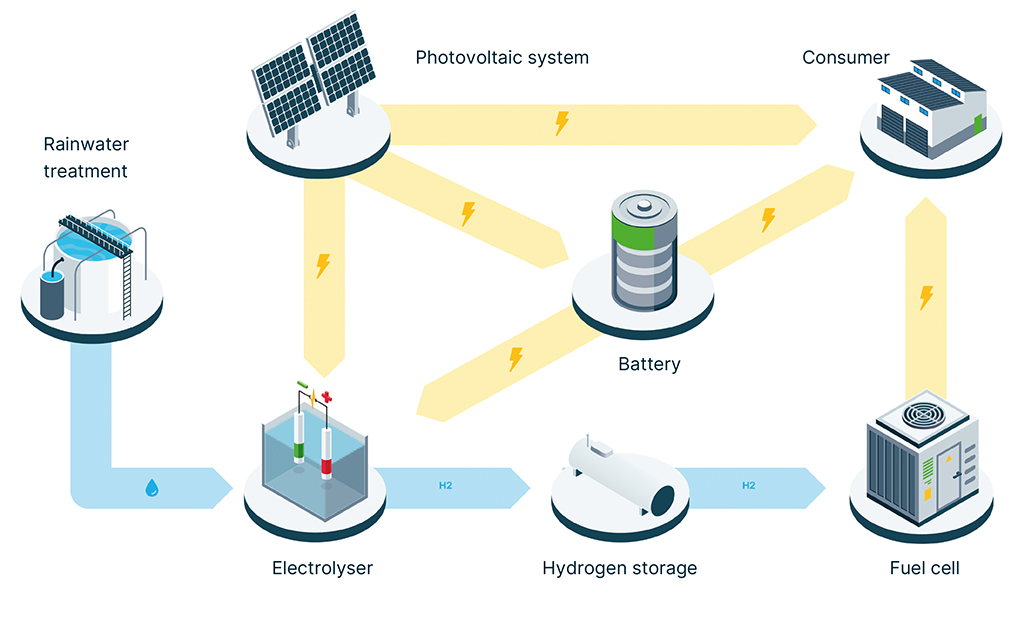

Having decided to proceed with the comprehensive and virtually self-sufficient energy supply at the new site, the biggest challenge was to work out a concept for all components, how they would mesh together and suitable sizing. After all, a ready-made blueprint for a solution like this did not exist. Jens Schuler is Project Manager for the system at Weckermann. We had to work it out as we went along, recalls the trained electrician, technician and industrial engineer. What was important was the willingness to try new things – in this regard, the Weckermann company, which produces more than 300 new products every year, certainly has the right mindset.

Our energy system is second to none – which gives us a competitive edge.

David Duttlinger, Managing Director of August Weckermann KG

Energy from the sun

The centrepiece of the energy system is two photovoltaic installations that generate electricity: one covering the entire roof of the building with a peak capacity of 700 kilowatts and another on the ground with peak power of 2,000 kilowatts. The rooftop panels alone are enough to cover the energy needs of production and the offices. In one year, the PV system produces up to 2,900 megawatt hours – in theory, enough to supply 800 homes for a year. Since August Weckermann operates three shifts around the clock, a solution is required for nighttime, when the PV modules are not generating any energy, and for times when power generation is low.

Using batteries for storage

Often, the rooftop PV system covers current energy usage. The electricity produced by the ground-mounted PV system is used to feed a battery with a storage capacity of 3.4 megawatt hours and a power output of 1,700 kilowatts. The incombustible, long-life battery is a lithium iron phosphate battery. It supplies the energy required for the night shift. The surplus electricity is used in the electrolyser for hydrogen production.

Rainwater electrolysis

The only electrolyser fed with purified rainwater can be found in Oberbränd at August Weckermann. Electrolysis normally uses drinking water but, at around 9 litres per kilogram of hydrogen, water usage is very high. Rainwater is collected in a 100-cubic-metre tank and purified before use. The electrolyser produces 5.4 kilograms of hydrogen per hour. The hydrogen is stored in four tanks, each with a volume of 115 cubic metres and a capacity of 1,400 kilograms. Each tank, which is 20 metres long and weighs 46 tonnes, is fitted with HEROSE safety valves. The valves are preset to 40 bar, plus all other components are able to withstand this pressure. If the pressure exceeds this level, the safety valves prevent damage to the system.

We are very happy with the system so far and the experience has been positive.

Jens Schuler, Business and Project Manager August Weckermann KG

Hydrogen production is up and running

The system has been producing hydrogen since May – around the clock when conditions are ideal – to fill the tanks for winter. If necessary, the stored hydrogen can be converted into electricity in the fuel cell. The heat given off by the fuel cell goes into the heating system. The waste heat from the machinery in production and from the compressed air system is also utilised. The heat pump controller decides whether the heat is used directly in the building or is fed into the fire water tank. This 200-cubic-metre underground tank is mandatory and serves as buffer storage in the system. If necessary, surplus heat is fed into the fire water and extracted again later. The minimum temperature of the water is 5 degrees and the maximum 18 degrees Celsius. In winter in particular, it makes a big difference whether the heat pump is operating on cold external air or on the pre-warmed water.

The energy system at August Weckermann is particularly comprehensive and makes the company virtually energy self-sufficient.

Sustainability through and through

Every aspect of the company’s energy system has been thought through, planned and implemented, based on a solid concept, using experienced partners and tried-and-tested technology. The new offices were built to German building energy efficiency standard KfW 40. After all, the site is at an altitude of almost 1,000 metres, meaning that the installed technology has to function at minus 20 degrees Celsius. The total investment cost of the energy system was 8 million euros, of which 2.5 million euros was a grant. Managing Director David Duttlinger reckons that the payback time is around 15 years. The icing on the cake, says Duttlinger, is the ability to sell surplus energy in the future – for example, to neighbouring companies – or to supply electricity to the other Weckermann facility three kilometres away. All told, the level of detail of the implemented energy concept is impressive – down to bringing in sheep to graze the ground beneath the solar panels. This saves time and cost of mowing and is also good for the environment.

August Weckermann KG

August Weckermann KG is a family-run manufacturer of precision-engineered parts based in the Black Forest highlands. The company, which was founded in 1885, manufactures premium turned and milled components. The name Weckermann is synonymous with reliability, precision and innovation thanks to its high level of in-house manufacturing capacity, state-of-the-art technology and a clear commitment to quality.

Read the current digital customer magazine now!

Read the current digital customer magazine now!