The Norwegian company YARA is one of the world’s largest fertiliser producers, with 12,500 employees in more than 150 countries. The production of ammonia, a major ingredient in artificial fertilisers, generates large amounts of carbon dioxide (CO2) which YARA processes in its own plants.

The YARA fertiliser plant in the Netherlands is located in Sluiskil on the Belgian border, while YARA Gas B. V., to where the carbon dioxide is transported by road for further processing into various products is 150 km further north, near Rotterdam. HEROSE has supplied the company with safety valves since 2010. Customer service is provided by Ron van de Weerd, the representative in the Netherlands.

Carbon dioxide is in great demand. In liquid form it provides the bubbles in soft drinks and as dry ice it keeps foods fresh. It can also be found in fire extinguishers, while in greenhouses it helps plants to grow better.

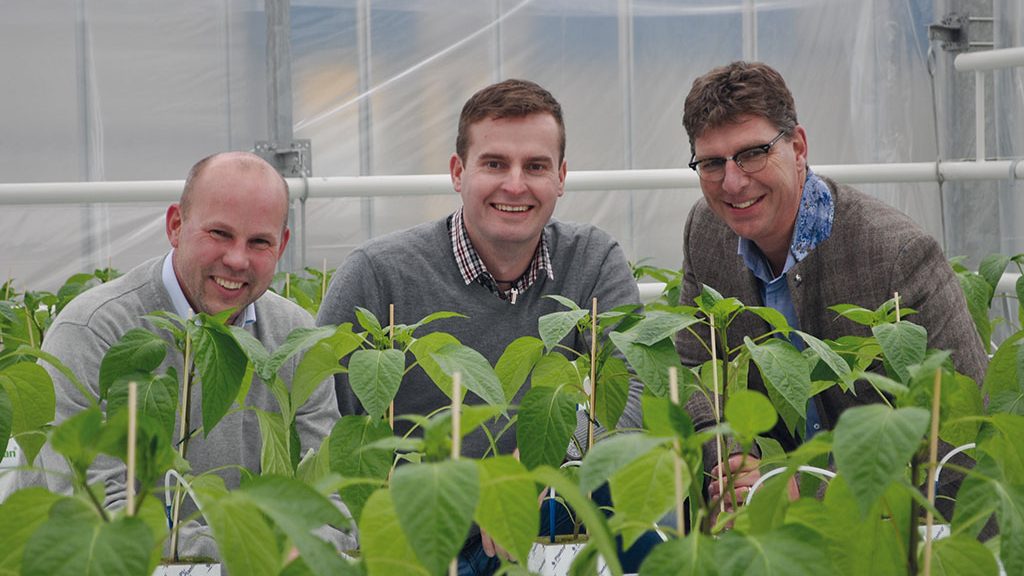

This is a subject that Peter de Vries can talk about for hours. He is the YARA Gas B. V. biologist – an internationally recognised expert who has his own greenhouse on the company premises. Here, he experiments all year round with various concentrations of CO2 – with the aim of further optimising plant growth. “The normal carbon dioxide content in the atmosphere is 0.03 percent”, says Peter de Vries, ” but we have found that 0.07 to 1.0 percent is optimal for plants in greenhouses.” The fact that YARA Gas B. V places a high priority on this aspect goes without saying for a Dutch company. Cultivation (usually in greenhouses) and sale of tomatoes and tulips is a mainstay of the Dutch economy. At the present time, more than ten million tulips are auctioned to customers from all over the world – every morning.

Pellets are the top sellers

A tour of the company with Fedde Kielman, Technical Manager YARA Gas B. V.. It is cold in the hall. “We are Europe’s largest dry ice producer”, says Kielman. “Last year, we supplied several thousand tons of it.” Various versions of dry ice are produced in Rotterdam: as cooling pads for service trolleys on aircraft, as blocks, or as pellets for surface cleaning. The greatest demand is for pellets, which YARA states as more as half of the total dry ice production. “We only produce to order” says Kielman. This is for a good reason, because dry ice loses five percent of its mass every day. “Customers who order before midday receive the goods in special containers the next day.” The largest customers include the airlines at Schiphol Airport in Amsterdam.

Low temperatures and high pressures are things which YARA Gas B. V. works with every day – and are the fields where HEROSE comes into play. Ron van de Weerd, who represents HEROSE in the Netherlands with his company VCC: “Our cryogenic valves are in demand in many sectors – from the trucks which transport the CO2 to the machines which produce the dry ice.” Van de Weerd estimates the number of replacements as about 100 valves per year – ranging from three-way valves and pressure regulators up to changeover valves.

Fedde Kielman and Ron van de Weerd have known each other for many years. Why does YARA Gas B. V. prefer to buy from HEROSE? “The overall package is excellent”, says Kielman. “What is important for us is the high quality of the valves – and HEROSE’s flexibility if we need to find solutions for new requirements in a short space of time.”

YARA International

YARA International is a Norwegian company with headquarters in Oslo, which produces chemicals and industrial gases such as fertilisers, urea, nitrates and ammonia. The company was founded in 2004 by the detachment from the parent company Hydro Agri, a division of Norsk Hydro. In Germany, YARA operates a distribution centre in Dülmen, a fertiliser plant in Poppendorf near Rostock and an ammonia and urea production plant in Brunsbüttel. YARA only produces carbon dioxide in Europe. There are dry ice plants in the United Kingdom, Ireland, France, Germany (Bad Hönningen) – and of course in the Netherlands.

Photos: Carsten Wurr

Read the current digital customer magazine now!

Read the current digital customer magazine now!