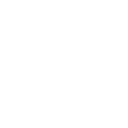

vc visited our colleagues at LORCH south-east of Stuttgart. A Report.

An industrial area in Filderstadt, within sight of Stuttgart Airport, is the home of the HEROSE subsidiary LORCH – a well-known specialist in the manufacture of safety valves for industrial applications. This morning, HEROSE Managing Director Dirk Zschalich has just flown in from Hamburg. A morning meeting with the local management and then an evening meal together with the employees are a small token of thanks from Bad Oldesloe for the good cooperation.

In Filderstadt, the twelve LORCH employees develop and assemble free release safety valves, angled safety valves and special safety valves for liquids, granulates and powders – in a wide range of different sizes and materials. “Made in Germany” in the best sense of the word – was one of the main reasons that HEROSE took over the company three years ago. Dirk Zschalich: “We as a group benefit from the know-how of the colleagues in Filderstadt, and we have also gained an additional customer base.”

Stefan Gil has been the plant manager since October 2015. The 36-year-old industrial engineer has worked for HEROSE since 2007 and before moving to Filderstadt, he was Head of Production Planning and Control in Bad Oldesloe. He has been one of the reasons for a considerable change in the management culture at LORCH. “One of my main concerns is to make the people who were affected by the takeover into motivated employees and to utilise their experience and know-how” , says Gil. The change from a patriarchal management culture to a modern management has been warmly welcomed by the employees. Wolfgang Schabel-Blessing from the Assembly department: “We are much more involved than we used to be.”

Why should the market buy from LORCH? Stefan Gil states three arguments: “For one thing, we are extremely flexible and can deliver most common valves within a matter of hours. As well as this, our products are of very good quality, with excellent value for money.” The company works continually to optimise its products – and to open up new international markets, further series of certifications is being aimed for.

Electronic test bench

Company mergers are usually used to achieve synergy effects. This is precisely the case with HEROSE and LORCH. Dirk Zschalich: “We have already achieved a great deal. Since November 2015, the entire purchase processes are handled by Bad Oldesloe, as are the Accounting department and HR. Development and Quality Management are now mainly concentrated in Bad Oldesloe.” An exemplary feature in Filderstadt is the digital test bench, with archiving all data which are relevant to the tests. Zschalich: “A system like this provides ideal conditions for smaller manufacturers who want to deliver high-quality products.” The proven testing system was set up by development engineer Günter Huber. The cross-company cooperation and learning from each other are the focus of Stefan Gil: “The regular exchange of employees, which we have already started, is to be further increase.” On the other hand, LORCH also benefits from the merger: with HEROSE the company in Filderstadt has had been backed by a financially strong mother company – as well as a large, global distribution network since 2013.

LORCH will soon be 100 years old

The Swabian company was founded in 1919 Initially, it specialised in repairing welding and cutting equipment, as well as pressure reducers for oxygen and other gases. In 1938 this was supplemented with regulators for neutral gases and air. In 1956 the range of products was extended to include needle valves, shut-off valves and branch valves. Production of safety valves and other compressed air products such as filters, regulators and filter pressure reducers began in 1960.

Finally, since 2006, LORCH has concentrated on the development and in-house production of industrial safety valves and the sale of commercial pro-ducts. Since 2013 LORCH is a member of the HEROSE Group – and therefore has great potential for the future.

Photos: Carsten Wurr

Read the current digital customer magazine now!

Read the current digital customer magazine now!